Product Details

|

Product Name |

Wheel hub |

|

Size |

Standard |

|

Material |

Steel |

|

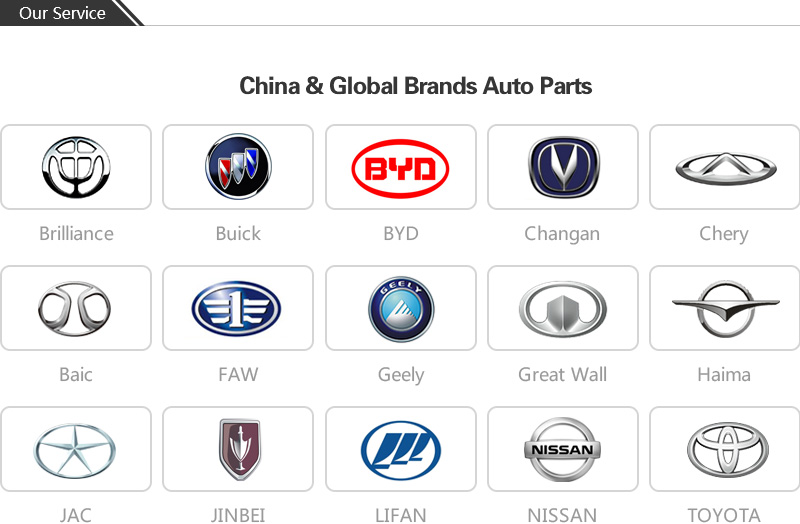

Car Application |

Chery T11 |

|

Place of Origin |

China |

|

Certification |

ISO9001/TS16949 |

|

Max Production Capacity |

1000 Piece/Pieces per Month |

|

Samples |

Charge |

1. Standard Exporting package.

2. Original package or neutral package.

3. According to clients ' needs.

4. Shipped in10-35 days after payment.

A. SASO for K.S.A

B. CIQ for Egypt, Ethiopia

C. COO, certified CI for Egypt, Argentina

D. Form A for European countries

E. Form E for Malaysia

F. Form F for Chile

G. COC for Algeria, Kenya, Bangladesh, Hatti, Nigeria

The main advantage of steel wheels is the simple manufacturing process, the cost is relatively low, and strong resistance to metal fatigue. However, the shortcomings of the steel hub is relatively prominent is that the appearance of ugliness, weight, inertial resistance, heat dissipation is relatively poor, and very easy to rust.

Relatively speaking, the alloy wheel can make up for such issues as light weight, low inertia resistance, high production precision, small deformation during high-speed rotation and small inertial resistance, so as to improve the straight running performance of the vehicle and reduce the tire wear Rolling resistance, thereby reducing fuel consumption. Alloy thermal conductivity is about three times than steel, good heat dissipation, for the vehicle's braking system, tire and brake system thermal attenuation can play a role. At present, the alloy wheels of the original car on the market are made mainly of aluminum alloy, and of course, many modified wheels will choose chromium, titanium and other elements as the basic materials in order to achieve certain special requirements and visual improvement. However, compared with the steel wheel hub, the alloy wheel prices are much more expensive, so often in many low-end level of the original car, the steel wheels will appear in the low with models, and alloy wheels are high with Standard models

Inquiry

Related Products